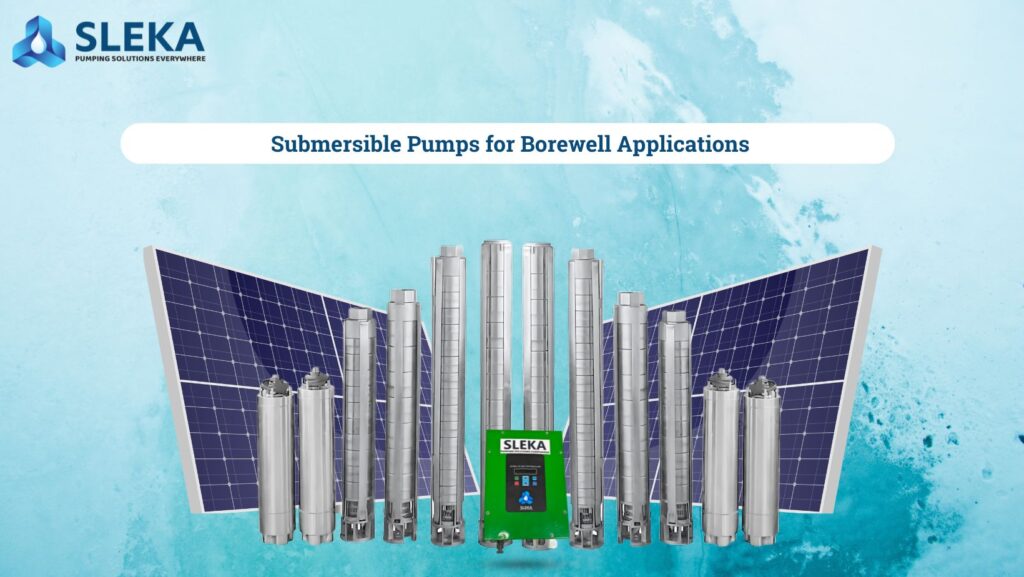

Submersible Pumps for Borewell Applications

In the world of agriculture and industrial applications, efficient water management is crucial. Submersible pumps have emerged as a preferred choice for borewell applications, providing reliable and effective solutions for various water extraction needs. In this article, we will explore the key aspects of submersible pumps, their working principles, and their advantages, helping you understand why they are an essential tool for farmers and industries alike.

Understanding Submersible Pumps

A submersible pump is a type of pump that operates while submerged in the fluid it is pumping, such as groundwater in borewells. Unlike conventional pumps that need to be installed above the water level, submersible pumps are designed to push water to the surface, making them more efficient in situations where the water source is deep underground.

Key Components:

- Motor: The submersible motor is sealed and waterproofed, enabling it to function effectively while submerged.

- Pump Stage: This part contains impellers that help in moving the water through the pump and out to the surface.

- Cable: A robust electrical cable connects the pump to the power source, transmitting energy to the motor.

How Submersible Pumps Work

The operation of submersible pumps is straightforward. When the pump is powered on, the motor starts rotating the impellers within the pump stage. As these impellers turn, they create a centrifugal force that pushes the water upward through the discharge pipe. This design eliminates the need for a suction line, allowing the pump to be more compact and efficient, especially in borewell applications where space can be limited.

Advantages of Using Submersible Pumps

-

Efficiency: Submersible pumps are highly efficient at lifting water from deep sources, particularly beneficial for borewells that can range from shallow to very deep depths.

-

Durability: Designed to withstand harsh conditions, submersible pumps are built with high-quality materials that resist corrosion, ensuring a longer lifespan with minimal maintenance.

-

No Priming Required: These pumps do not require priming, which means that they can operate effectively without the need to fill the pump casing with water before starting.

-

Quiet Operation: Due to their submerged nature, submersible pumps operate quietly, making them suitable for residential areas and situations where noise pollution is a concern.

-

Versatility: They can be used for various applications, including irrigation, drainage, and in industries for pumping fluids.

Conclusion

Submersible pumps have revolutionized water extraction in both agricultural and industrial sectors. Their efficiency, durability, and ease of use make them ideal for borewell applications where reliable water supply is essential. By investing in quality submersible pumps, farmers and industries can ensure they have a dependable source of water, supporting productivity and operational success.

FAQ

-

What depth can submersible pumps operate at?

Submersible pumps can operate at various depths, typically ranging from a few meters to over 300 meters, depending on the pump design. -

How do I maintain my submersible pump?

Regular maintenance includes checking the electrical connections, inspecting the cable for damage, and ensuring the motor is properly ventilated. Routine professional servicing is also recommended. -

Can submersible pumps be used in dirty water conditions?

Yes, there are submersible pumps specifically designed for dirty water and sewage applications, featuring larger impeller passages to handle solids.

Investing in a reliable submersible pump from SLEKA can enhance your water management strategy, bringing efficiency and reliability to your agricultural or industrial operations.