7 Essential Tips for Maximizing Your Stainless Steel Pumps

When it comes to pumping solutions, stainless steel pumps are renowned for their durability, corrosion resistance, and efficiency. Whether you are managing a commercial operation or setting up a residential water system, understanding how to maximize the performance of your stainless steel pumps can lead to significant benefits. In this guide, we will delve into essential tips that will help you get the most out of your stainless steel pumps.

Understanding Stainless Steel Pumps

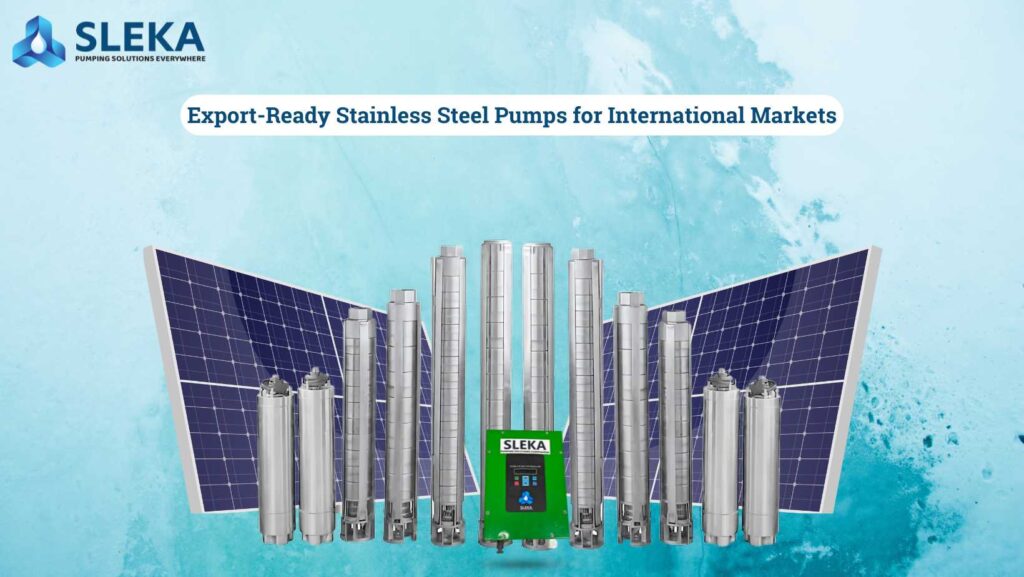

Stainless steel pumps are designed to handle a wide range of fluids, including water, chemicals, and other liquids. Their robust construction makes them ideal for both industrial and agricultural applications. Sleka specializes in submersible pumps that utilize stainless steel materials to ensure longevity and reliability. With the right maintenance and usage practices, these pumps can serve effectively for years.

1. Choose the Right Pump for Your Application

Before purchasing a stainless steel pump, it is crucial to assess your specific requirements. Factors like flow rate, head height, and the type of fluid being pumped will determine the best pump for your needs. Sleka offers a range of submersible pumps tailored to various applications, from irrigation to sewage management. By selecting the appropriate model, you can optimize performance and energy efficiency.

2. Regular Maintenance is Key

To ensure the longevity of your stainless steel pumps, regular maintenance is essential. This includes checking for wear and tear, cleaning filters, and inspecting seals and bearings. A well-maintained pump not only performs better but also reduces the risk of unexpected breakdowns. Sleka provides detailed maintenance guides for its submersible pumps, making it easy for users to keep their systems running smoothly.

3. Monitor Operating Conditions

Understanding the operating conditions of your pump can significantly affect its performance. Factors such as temperature, pressure, and the viscosity of the fluid being pumped play crucial roles in pump efficiency. For instance, running a pump outside its recommended pressure range can lead to cavitation, which damages the pump over time. Always refer to the manufacturer’s specifications provided by Sleka to ensure optimal operating conditions.

4. Proper Installation Techniques

The installation process of your stainless steel pump can greatly influence its effectiveness. Ensure that the pump is installed level and securely anchored to prevent vibrations and movement during operation. Additionally, follow any specific installation guidelines provided by Sleka for submersible pumps to avoid common pitfalls that could lead to decreased performance or damage.

5. Use Quality Accessories

Using high-quality accessories such as hoses, fittings, and valves can enhance the performance of your stainless steel pumps. Poor-quality components can lead to leaks, reduced flow rates, and increased wear on the pump itself. Sleka offers compatible accessories for its submersible pumps, ensuring that every part works harmoniously for maximum efficiency.

6. Optimize Energy Usage

Energy efficiency is a crucial aspect of operating stainless steel pumps. By utilizing variable frequency drives (VFDs), you can control the speed of the pump motor based on demand, which reduces energy consumption significantly. This not only lowers operational costs but also extends the lifespan of the pump. Consult with Sleka for advice on energy-efficient solutions tailored to your pumping needs.

7. Understand When to Replace Your Pump

Even with proper maintenance, there comes a time when replacement is necessary. Signs that your stainless steel pump may need replacement include unusual noises, reduced flow rates, and frequent breakdowns despite maintenance efforts. Regular inspections can help you identify these issues early on. When it’s time to replace your pump, consider Sleka’s range of submersible pumps that continue to deliver reliability and performance.

Frequently Asked Questions (FAQ)

FAQ #1: What are the advantages of using stainless steel pumps?

Stainless steel pumps offer corrosion resistance, durability, and ease of maintenance. They are suitable for various applications and can handle aggressive fluids without degrading over time.

FAQ #2: How often should I perform maintenance on my stainless steel pump?

Regular maintenance should be conducted at least once every six months or more frequently depending on usage conditions. Following the maintenance guidelines provided by Sleka will ensure optimal performance.

FAQ #3: Can I use stainless steel pumps in corrosive environments?

Yes, stainless steel pumps are designed to withstand corrosive environments due to their resistant material properties. However, always check the specific compatibility with the fluid being pumped.

FAQ #4: What types of fluids can stainless steel pumps handle?

Stainless steel pumps can handle a wide variety of fluids including water, chemicals, oils, and wastewater. Ensure that the specific model is rated for the type of fluid you intend to pump.

FAQ #5: How do I know which size pump I need?

Determining the correct size involves calculating the required flow rate and head height based on your specific application needs. Consulting with professionals or using guides from Sleka can help you make an informed decision.

FAQ #6: What is cavitation and how can I prevent it?

Cavitation occurs when vapor bubbles form in a liquid due to low pressure and then collapse violently when they enter higher pressure areas. To prevent cavitation, ensure your pump operates within specified pressure ranges as outlined by Sleka.

FAQ #7: Where can I find quality submersible pumps?

You can explore Sleka’s extensive range of submersible pumps designed for various applications on their products page.

Wrapping Up

In conclusion, maximizing the performance of your stainless steel pumps involves understanding their capabilities, ensuring proper installation and maintenance, and selecting quality components. For those interested in high-quality submersible pumps tailored for various applications, be sure to visit Sleka’s product page.

To know more about solar pumps in agriculture, visit- Sleka Solar Pumps.

To know more about Noryl impellers and diffusers, do visit- Nobtech Products.

By following these essential tips and leveraging Sleka’s expertise in submersible pumping solutions, you can enhance efficiency and prolong the lifespan of your pumping systems significantly.